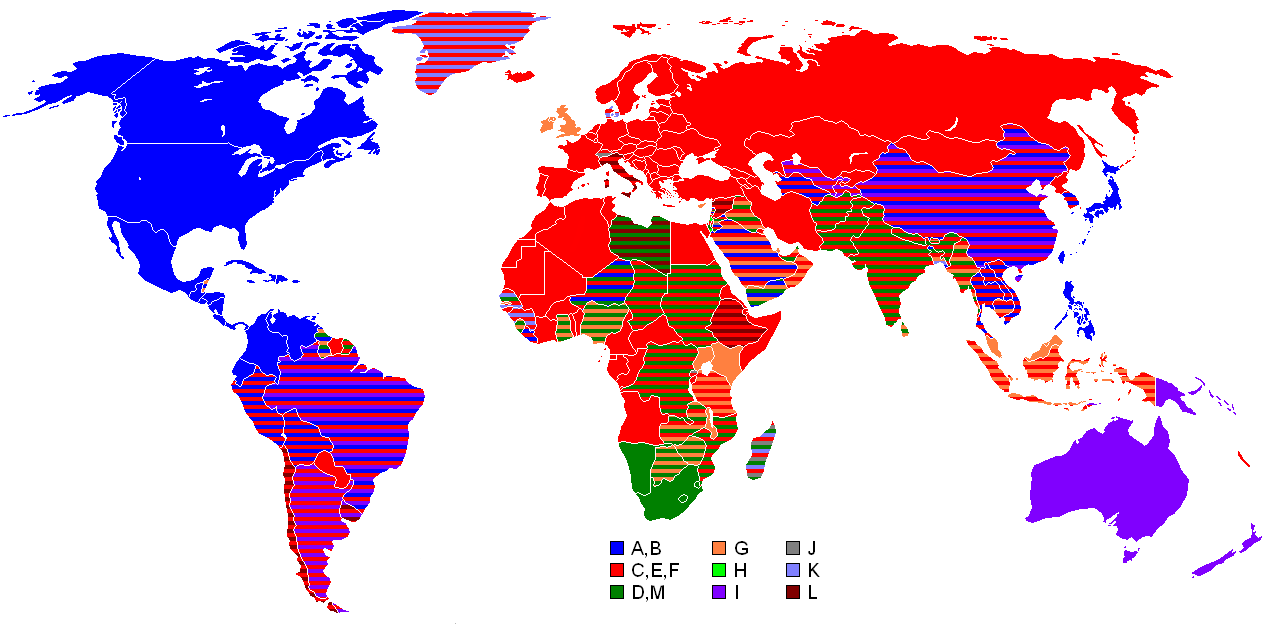

We need to standardize wall plugs, as we have done with USB-C for electronics (and the future USB-4 protocols for the USB-C standard, I hope).

Companies have several versions of the same products with different plugs for different countries, and the customers must make sure that they have chosen the right plug for their sockets. When the only option available is not the right one for their country, they have to buy additional adapters and complicate their lives for nothing.

As more and more people install solar panels and batteries in their homes, more and more people get to choose what frequency and voltage they want to use. They can change their inverter or its settings (Unless the government prohibits it, obviously).

I'm sure this can be standardized, and it will be cheaper than making every device in the world dual-voltage and dual-frequency, and making several versions of every product for several sockets... and spending the time to choose the right plug... Also, people live more and more globally, not stuck into a single country. So the problem will become worse over time.

Our time and effort is way more valuable than the cost of changing plugs or alternators, and the longer we stay without a good standard, the more resources we will waste in the future. It's not a bad idea to remove a bad standard, like the European schuko or Type F plug.

Type F plugs are hard to plug in and out. Sometimes they're so stuck that if you pulled from the cable itself, the force required to unplug it would be so great that you would risk damaging the cable before even getting it unplugged. If the socket is not well fixed in place (like most power strips) you will need both hands to do it. Maybe you will need to grab the plug from the tiny slit between it and the socket, with the risk of getting electrocuted by touching the connectors.

Therefore any argument defending this hard-to-pull feature for security is absolutely invalid.

Type F plugs are also quite big, and it doesn't seem like the cheapest build. Let's ditch them.

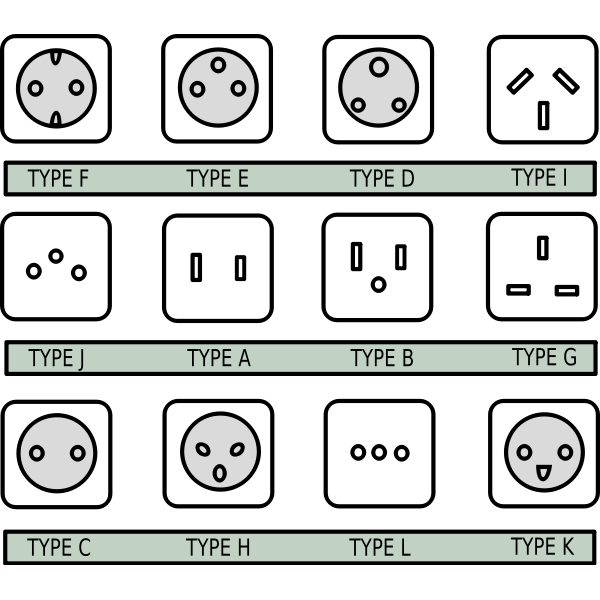

The american or Type A connector is at least cheap and simple (even though unsafe), and the British or Type G is safe (even though unnecessarily big).

Requirements

To find the perfect plug/socket I will set several requirements:- The shape of the socket holes should be curved, so that one can easily insert the connector without having to nail it perfectly over the hole. Like the type A, B, I, plugs.

- With AC it's not a good idea to be able to plug things in both ways. One cable is neutral, but the other cable alone can kill you. I like them differentiated. (If it can be plugged in both ways but the cables are always with the same connection, then it's good). For example a E27 (Edison Screw) bulb socket has a very exposed metallic thread that connects the neutral wire, and some internal pins with the phase. If you interchanged the neutral by the live wire (by flipping a lamp plug for example), touching the bulb cap could kill you. Better polarized outlets with ground.

- If it always plugs in the same way, then we can start taking security measures such as making the internal ground and neutral cables longer than the phase, so that a pull will cut the power rather than the ground connection. This way you can easily improve the safety, like the Type G or British plug does. This will likely not apply to injection molding plugs though.

- The ground connector should be metallic from the beginning, while the phase and neutral should have plastic sleeves. This way the live pins are always hidden when connected, and any random movement during an electrocution will easily touch the ground, causing only the fingers (or small objects, but not the heart) to get electrocuted, and a clear current differential that will likely activate the main automatic switch (the breakers).

- A longer ground pin would guarantee that while the phase is connected the ground is always connected. This way an appliance with a short to its case will trip a circuit breaker instead of electrocuting the user. The ground pin could also be thicker so it doesn't fit into the live socket hole. Maybe this can be achieved by the internal connectors of the socket. I suppose that having all plug pins of the same size can simplify the production.

And nice features:

- Be able to use a standard socket with a plug that has no ground, with only 2 pins.

- I don't mind fuses for redundancy, but don't rely on them. With the long circuitry of a house, we should rely on the main breakers cutting short-circuits (too much current for a short amount of time) and leakage current (differential).

Also, very important, the power strips should have overload protection. The current of several appliances might be okay for the main circuit of the house, but too high for a power strip or just a 16A cable. They should also have surge protection, to protect expensive electronics from over-voltage due to bad networks or lightnings.

Each socket should be rated for at least 16A at 220-240V (3.7KW).

We should make sure it's impossible to plug the ground pin into the phase of the socket.

The smaller, more stackable (in a power strip), cheaper, and the more durable they are, the better. The socket should wear very little.

Plugs

The British (Type G) plug is quite good, but it's bulky and cannot handle much power (~3KW).The American (Type A) plug is simple and cheap, but too dangerous for 230V AC power.

The best already-existing plug that I have found is the Type N plug (IEC 60906-1):

It turns out the IEC issued the Type N plug (IEC 60906-1) as the International Standard for a universal plug: https://www.iec.ch/worldplugs/why_so_many.htm

It is polarized (only one way) and grounded, very compact, and supports 16A (A variation in Brazil is rated for 20A). With a recent design (using injection moulding), it is very compact, robust, and safe. Type N sockets are compatible with Type F (European Schuko), Type C (Simplified Type F), Type E, and Type L plugs.

The socket holes are not usually curved, they don't have fuses, and probably they don't have wires of different length (maybe it's useless to do so with a solid piece of plastic. I haven't found any information). However, all these modifications can be easily added, if necessary, without modifying the overall design. I would also like some slight dents to keep the plug in at the right depth and to provide some feedback to the user when it is well plugged. This way you don't depend on the plastic to keep the plug inserted. But it would require a major design change.

Fortunately I don't think it's possible to plug the ground into the live with type N sockets, and I'm not sure if it contacts the ground and the live at the same time. I would like deep live and neutral contacts so that they're the last to connect, and they're also hard to reach for children.

Either way, I think the overall design is very good.

I'm open to change my opinion and find a radically better plug and socket, but for now I think this is the best one we can use. It has already been adopted by Brazil and South Africa.

| https://www.iec.ch/worldplugs/typeN.htm |

Type N plug dimensions

They're 19mm long, 4, 4.5, or 4.8mm in diameter. The phase and neutral tips are 19mm apart, with 10mm long sleeves, and the ground is 3mm from the line that joins the phase and the nutral.

Questions

- Could we use a circular plug for this type of voltages? Like the standard 12V DC port for Laptops (5.5mm x 2.1mm Barrel connector).

- Is it really better to use circular pins instead of flat ones like the American Type-A plug?

- Why not the IEC C14?

Comentarios

Publicar un comentario